Contact Us

- No.31 Xianghong Road, Xiang'an Distrcit, Xiamen City, Fujian Province, China

- echo-wang@eahunt.com

- +86-592-7616732

Class 2 12V Power Supply

bluetooth echo charging requires 5V DC power supply, but the mains power supply is 220V AC power supply. In order to charge the mobile phone normally, a power adapter is needed to convert the mains power that cannot be directly used by the mobile phone to 5V DC power

Description

Description

Adapter 9 Volt DC,The adapter is suitable for converting the interface of one class into another interface desired by the customer, so that the classes that cannot participate in the work due to interface incompatibility can work together.

Techinical parameters

Input Specification | Electrical | Tests Environmental |

Voltage: 100-240VAC | Voltage Accuracy: ±3% | Hi-pot Test: 3750VAC, 60S, 5mA max |

Frequency: 50-60Hz | Current Accuracy: ±3% | Lightning surge: up to 1000V (accept 3000V) |

Output Specification | Efficiency:DOE | Leakage Current: 0.25mA max |

Voltage:5V,9V,12V | Securityprotection: SCP,OVP,OCP,OTP | Burn-in Test: rate load, 40±3℃, 4 hours |

Current:0.5A-1A | Turn On Time:15-30mS | Operating Temperature:0-40℃ |

Power:12W | Burn-In Test:100% Full Load | Storage Humidity 5%-95%RH

|

Selection of components for Class 2 12V power supply

Because the components directly determine the reliability of the power supply, the selection of components is very important. The failure of components mainly focuses on the following four aspects.

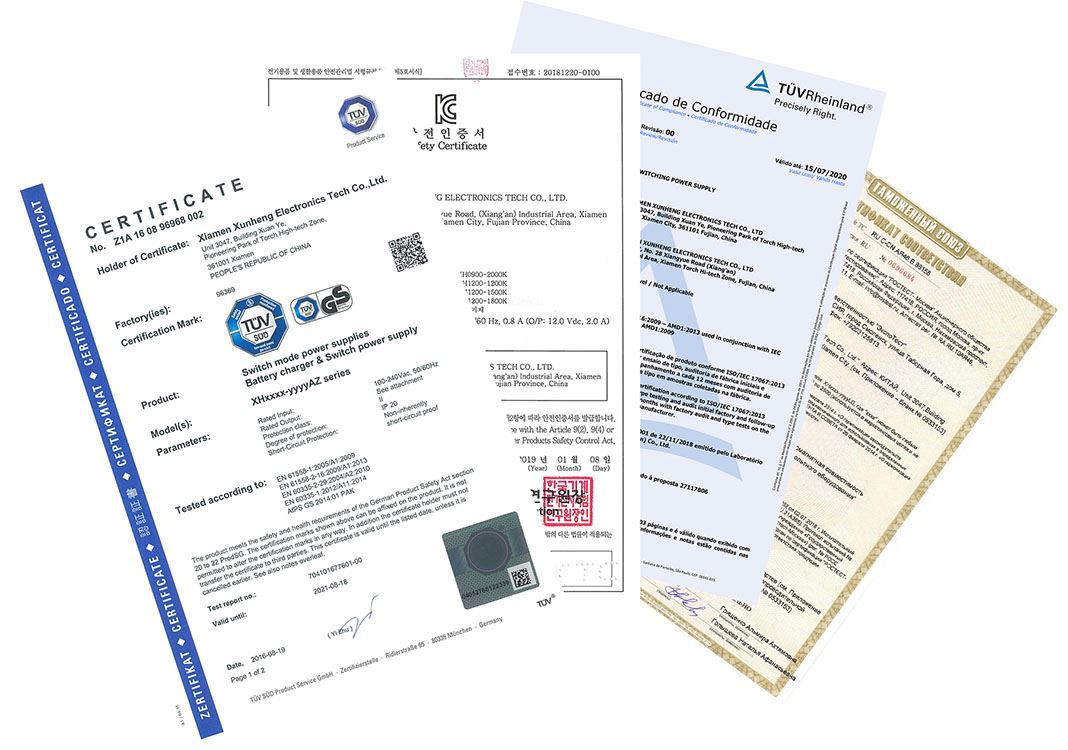

(1) The failure caused by manufacturing quality problems has nothing to do with working stress. Unqualified products can be eliminated through strict inspection. Mature products from designated manufacturers shall be selected during engineering application, and products without certification are not allowed.

(2) Component reliability problem component reliability problem, that is, the problem of basic failure rate, which is a random failure. The difference from quality problem is that the failure rate of components depends on the working stress level. Under a certain stress level, the failure rate of components will be greatly reduced. In order to eliminate the components that do not meet the use requirements, including unqualified electrical parameters, unqualified sealing performance, unqualified appearance, poor stability, early failure, etc., screening test shall be carried out, which is a non-destructive test. Through screening, the failure rate of components can be reduced by 1 ~ 2 orders of magnitude. General requirements for screening test of main components of power supply equipment: ① resistance shall be tested 100% according to technical conditions at room temperature, and unqualified products shall not be removed. ② Ordinary capacitors shall be tested 100% according to the technical conditions at room temperature, and do not remove unqualified products. ③ The connector shall be sampled and tested for various parameters according to the technical conditions. ④ Semiconductor devices shall be screened according to the following procedures: visual inspection, preliminary test, high temperature storage, high and low temperature impact, electric power aging, high temperature test, low temperature test and normal temperature test. After screening, the rejection rate q = n / N shall be calculated × 100% (6-23), where: n - total number of tested samples; Number of rejected samples.

If Q exceeds the upper limit value specified in the standard, all components in this batch are not allowed to be put on the machine and shall be handled according to relevant regulations. When the standard is met, paint the qualified components and parts and mark them, and then enter the special warehouse for installation.

Hot Tags: class 2 12v power supply, China, suppliers, factory, customized, price, for sale

You Might Also Like