Contact Us

- No.31 Xianghong Road, Xiang'an Distrcit, Xiamen City, Fujian Province, China

- echo-wang@eahunt.com

- +86-592-7616732

Medical Power Adapter

Medical device power supply,12V5A for medical equipment with high efficient,stable and security

Description

Description

Power supply for medical equipment,it widely used in the field of medical imaging, it is suitable for ultrasound, endoscope, breast machine, digital X-ray, fundus scanner, medical display, etc. The products have obtained iec60601-1, ul60601-1 and en60601-1 certification, meet 2mopp, meet the standard of the sixth generation energy star, and pass the ISO13485 system certification. The standby power consumption is small, the efficiency is high, and the average failure free time is 100000 hours.

Specification

Medical and ite safety certification

2 MOPP isolation protection

Medical equipment up to BF (Λ) level

Contact current ≤ 250 μ A

Standby power consumption ≤ 0.5W

12V to 48V output, up to 120W

Working altitude: 2000m

There are 3 types of AC sockets for input

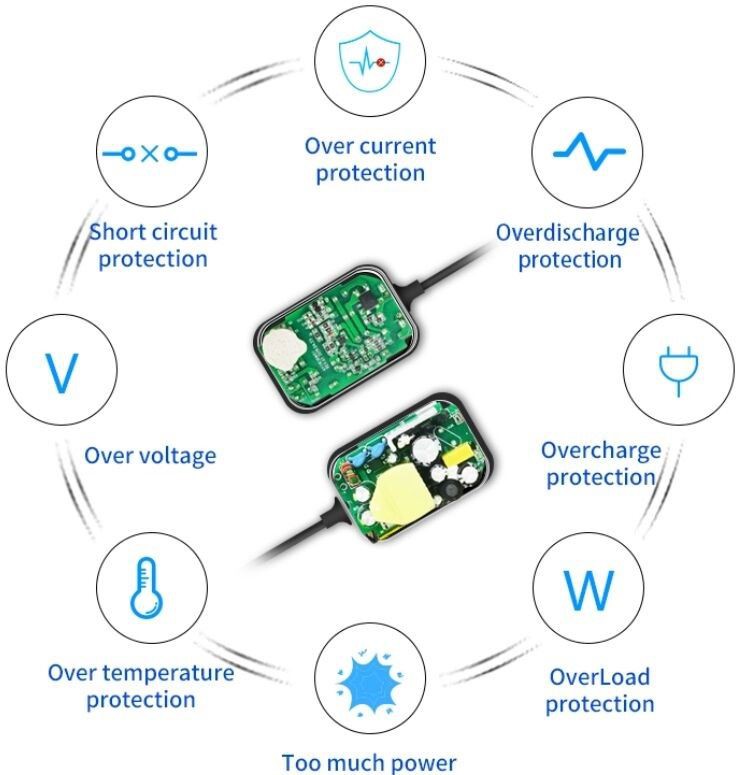

It covers short circuit protection, overvoltage protection and overload protection;

Electrical specifications

Input voltage: 90 ~ 264Vac

Input current: 2A

Standby power: 0.5W

Output voltage range: ± 5%

Environmental parameters

Operating temperature: 0 ~ 40 ℃

Storage temperature: - 20 ~ 80 ℃

Working humidity: 10 ~ 90%

Storage humidity: 5 ~ 90%

In the medical industry, because it is related to people's life safety, all related products will give priority to quality. In this case, how should we choose medical power supply?

As we all know, each industry has certain hard indicators for power supply, and the medical industry is no exception. If the power supply can be used in medical devices, it must first pass the corresponding indicators of medical certification.

1. EMC index requirements:

The conduction and radiation of medical equipment shall meet en55011, and the limit is the same as that of en50552 ite equipment. Considering that the medical system should meet the requirements of high safety and high isolation, and the conduction and radiation should also meet the standard requirements, which is a great test for the design of power supply. In fact, it is very difficult for designers to ensure high isolation and EMI in the design, so many medical equipment have to compromise, Only EMI performance is required to meet classA level.

2. Safe distance and withstand voltage:

The medical standard is different from the conventional certification. In order to ensure safety and reliability, the safety distance and pressure resistance index requirements of the system are clearly specified in the standard. These distance and pressure resistance requirements will be distinguished according to the application and population. They are divided into MOPP (patient protection mode) and moop (operator protection mode) according to the protection mode, and into class B, BF CF class. Considering the universality of the module, medical power engineers usually meet the most stringent requirements as far as possible in the design process, which are as follows: ① L and N are isolated from PE 1500vac, the electrical clearance is 2.5mm, and the creepage distance is 4.0mm. ② The primary side to secondary side of the transformer is 4000vac, the electrical clearance is 5mm, and the creepage distance is 8mm. ③ Output to PE, 500VDC (floating ground), electrical clearance 2.5mm, creepage distance 4mm.

3. Requirements for ultra-low leakage current:

Low leakage current is the core index of medical power supply. IEC requires medical equipment to test 264Vac, 50Hz and leakage current ≤ 500uA under normal conditions. However, medical equipment usually has more than one isolated power supply, and some large CT even has 5 or more power supplies. Therefore, for power supply manufacturers, the leakage current of a power module should be ≤ 100ua. For the post level DCDC power supply in contact with the human body, the isolation requirements are more stringent because it is in direct contact with the human body, especially for CF equipment in contact with the heart, which is clearly required to be ≤ 10uA in the medical certification.

4. Requirements for grounding continuity:

The main reason why the medical power supply has requirements for this index is that when the grounding resistance is large, it is easy to lead to a large difference in the ground potential of equipment powered by different power supplies, which may be harmful to seriously ill patients. Therefore, the grounding continuity must also be strictly tested. IEC requires that the resistance of PE to any accessible metal of the shell is less than 0.1 Ω.

5. Other requirements:

In addition to the above conventional requirements, medical equipment also needs to meet all the requirements of conventional civil appliances. For example, it needs to meet the requirements of RoHS, and the temperature that can be touched by hands must meet the requirements of conventional standards. It is not listed in detail.

Hot Tags: medical power adapter, China, suppliers, factory, customized, price, for sale, inverter board assembly, electronic board manufacturing, high volume pcb assembly, pcb design and assembly, electronic assembly fabrication smt board assembly, pcb components assembly

You Might Also Like